A World First

on-press speed and safety

SONO works on-press, so there’s no need for painfully slow and potentially dangerous anilox roller removal, and you don’t need the team of Maintenance Engineers to do it.

Think about it: all that time, equipment and health & safety risk that comes with preparing your rollers for cleaning, all gone. Because rollers are cleaned by print operatives in-situ, there’s no chance of damaging them. No maintenance crew involvement, and no forklifts, docking units, carrier trolleys or hoists. It’s just one more way SONO helps reduce the everyday challenge of running your flexo smoothly.

-

Your roller stays installed

SONO is on-press so there’s no need to remove your roller for cleaning which prevents potential costly damage.

-

Sono SmartGuide docking technology

SONO’s lightweight design and SmartGuide docking system means that just one operative can perfectly install SONO on-press for every clean.

Ultrasonic

technology

For consistently clean rollers and no risk of damage to them, no other system touches ultrasonic technology. SONO uses proven ultrasonic engineering to clean millions of individual cells quickly and consistently. In fact, SONO allows you to achieve industry best performance as well as giving you the ability to prove it to your customers. Your ink supplier has control of the ink; your repro team has control of the plates; and now you have control of the anilox volume. Holding ΔE and providing spectral data reports to your customers stops being a headache. Instead, it starts to be standard procedure, because SONO guarantees 100% clean cells right across the whole width of the roll, every time.

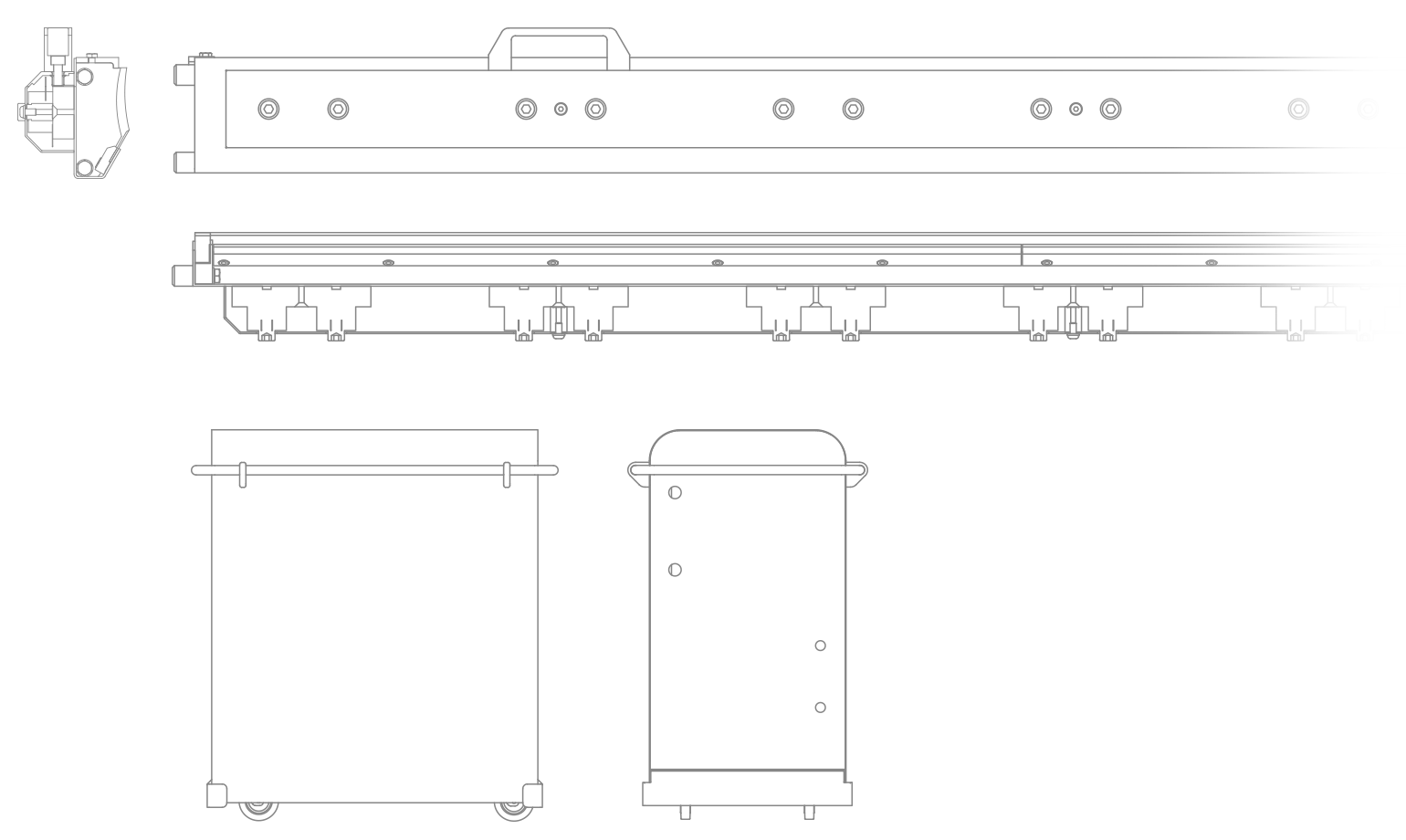

SONO consists of three key components:

Pod console

This component is the brains of Sono, it incorporates the generators for the ultrasonics, the pump, the control system, the cleaning solution and dosing systems, all the technology and sequencing information to allow the Sono bar to meet your requirements.

Sono

This component contains the ultrasonic transducers mounted to the cavity that encapsulates the solution to clean the anilox roller 100%.

Smart Guide

Absolute’s unique docking system ensuring perfect location of Sono against your anilox, and designed specifically to complement each individual print unit.