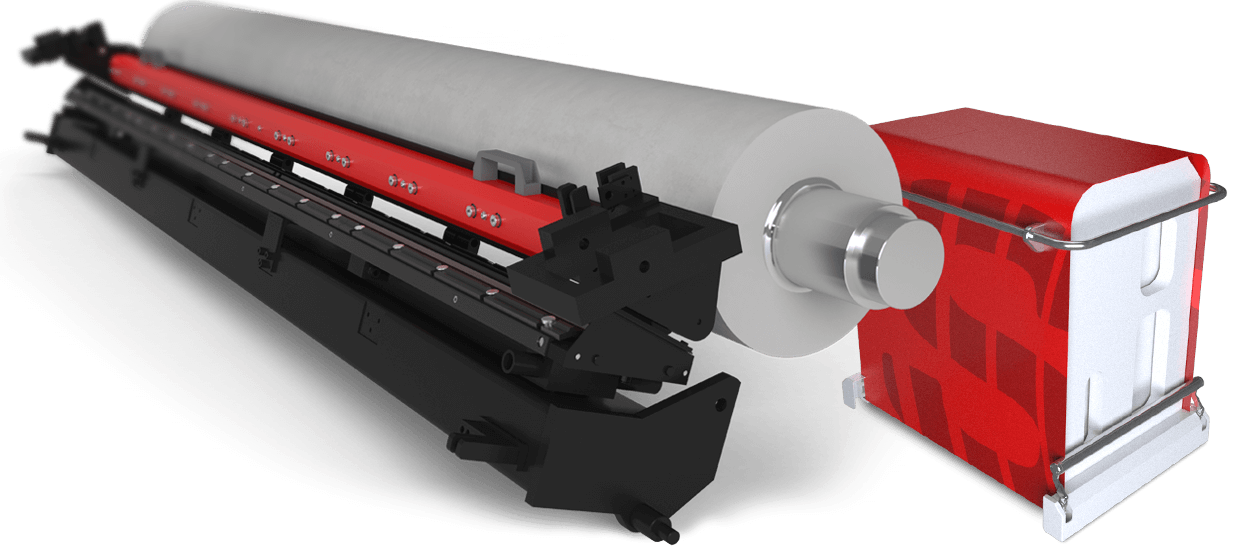

The world's first on-press ultrasonic anilox cleaner

Watch the videoThe Product

Smart. Consistent. Fast.

Take control of ink and colour management on your flexo. There’s never been an on-press anilox cleaner capable of 100% cell retrieval – until SONO.

As the world’s first and only ultrasonic on-press cleaner, SONO changes everything. In fact, anilox cleaning will never be the same again. Now you can control the heart of your flexo station and guarantee your customers the consistent colour management they insist on.

Performance

Ultrasonic. Ultra-fast

Having dirty anilox cells is the biggest cause of defects in flexo, and it leads to manual intervention. Adjustments to ink are hugely expensive both in material terms and lost output, so how can you win back capacity in your plant at no cost? Simple: by controlling colour so that the norm is right first time, on-press and on-colour.

With SONO, this becomes the reality, and the payback in terms of increased ‘no cost’ capacity is huge. After all, print line downtime kills productivity. When it comes to maximising your machinery’s runtime over weeks, months or years, nothing comes close to SONO.